Industrial computed tomography

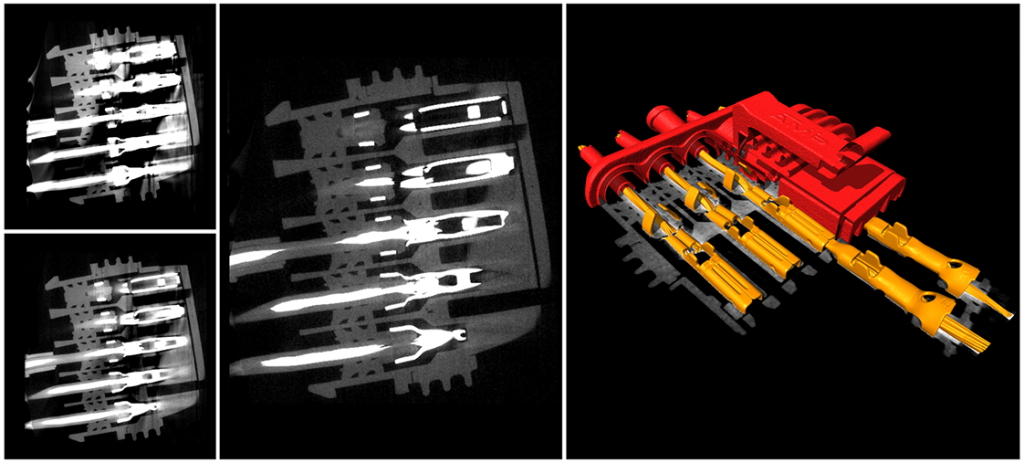

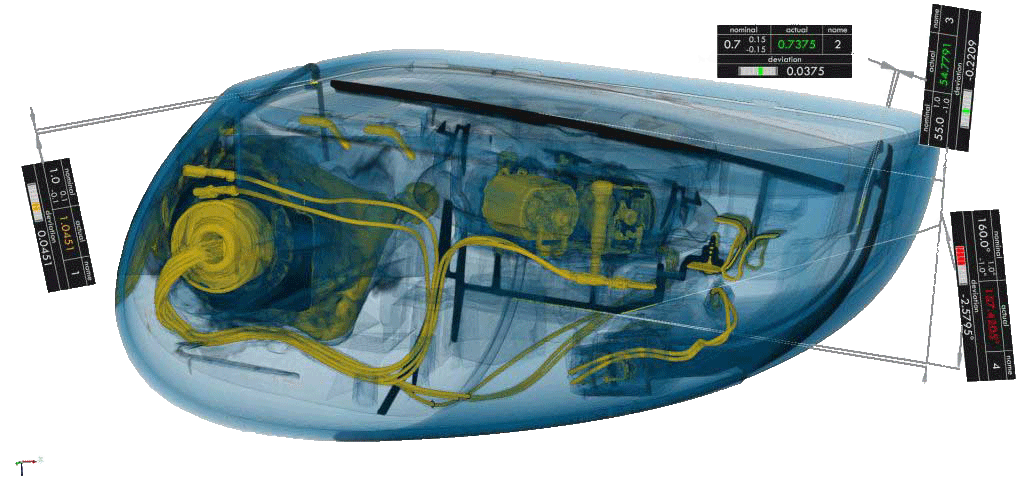

Imaging by means of computed tomography enables non-destructive testing and measurement of areas of components, assembled assemblies or even composite components that are not accessible at all or only to a limited extent.

In contrast to all other scanning methods, a component or assembly group can be recorded in its entirety, thus offering a much wider range of evaluation options.

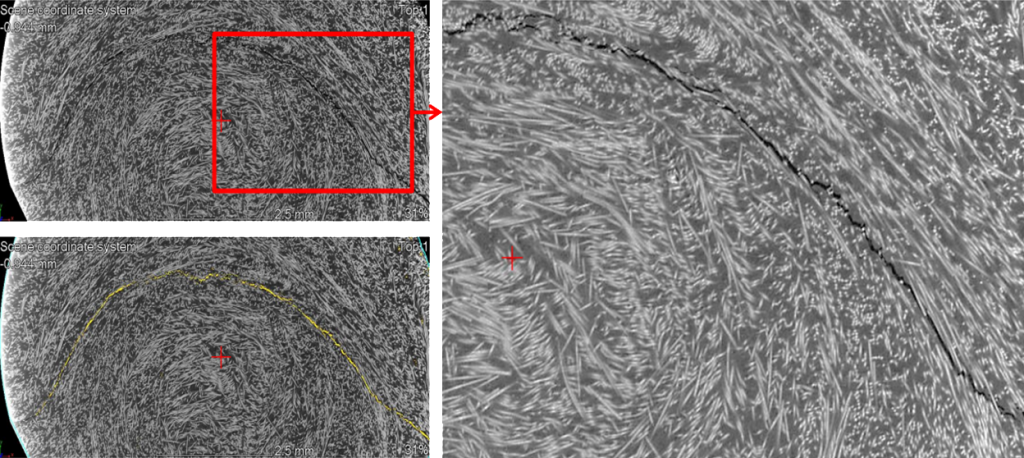

In addition to the classic evaluations of dimensions, shape and layers, this also enables analyses of the material structure such as:

- porosity / inclusion detection (Lunker analysis)

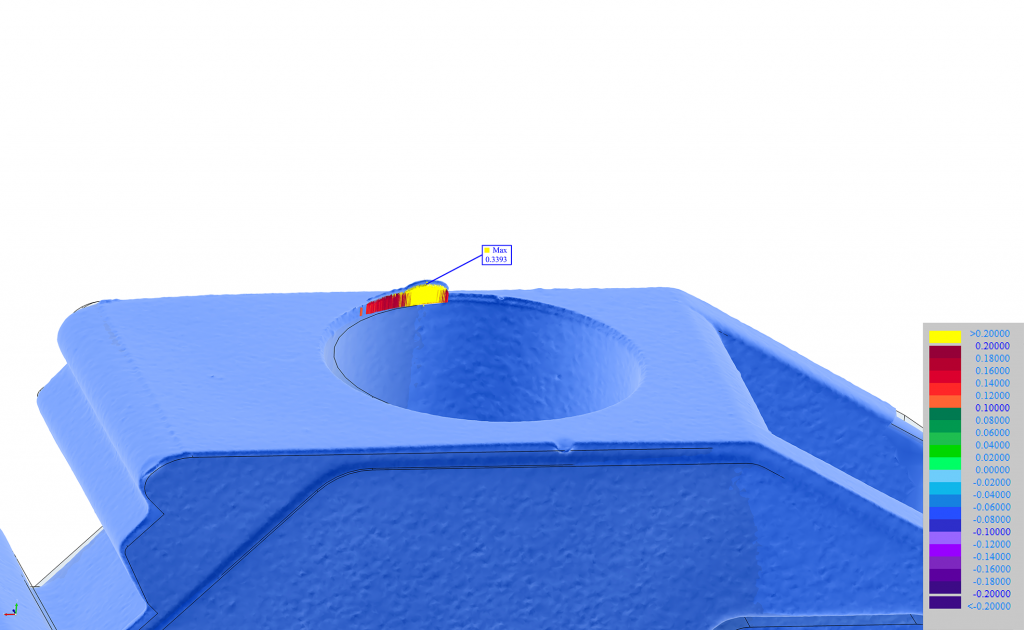

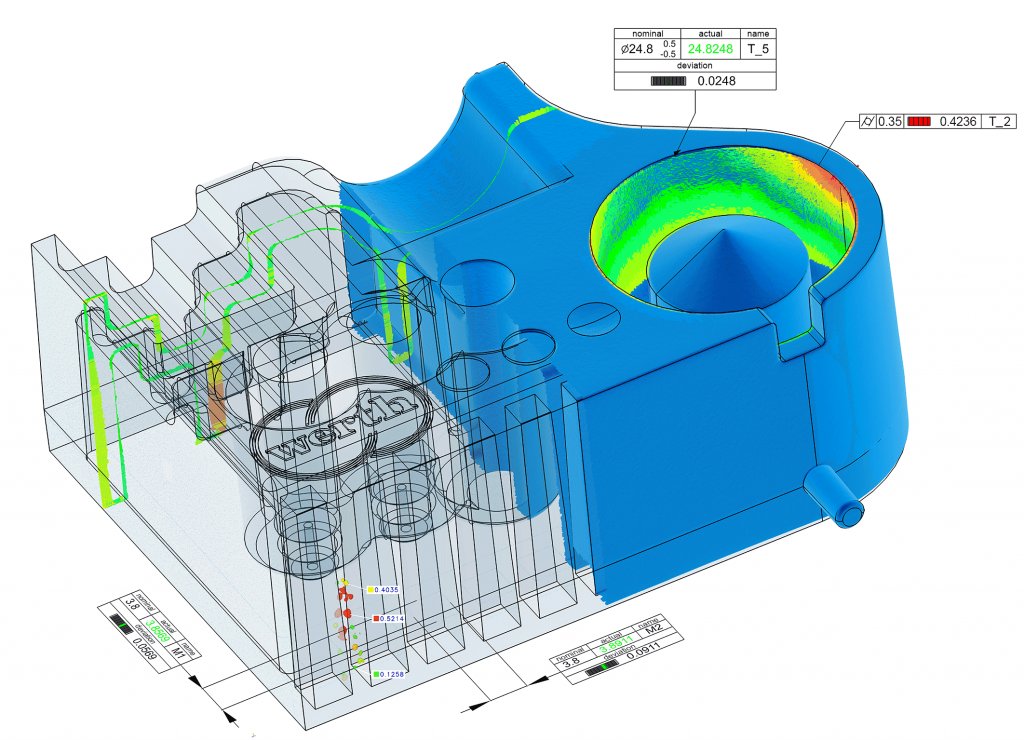

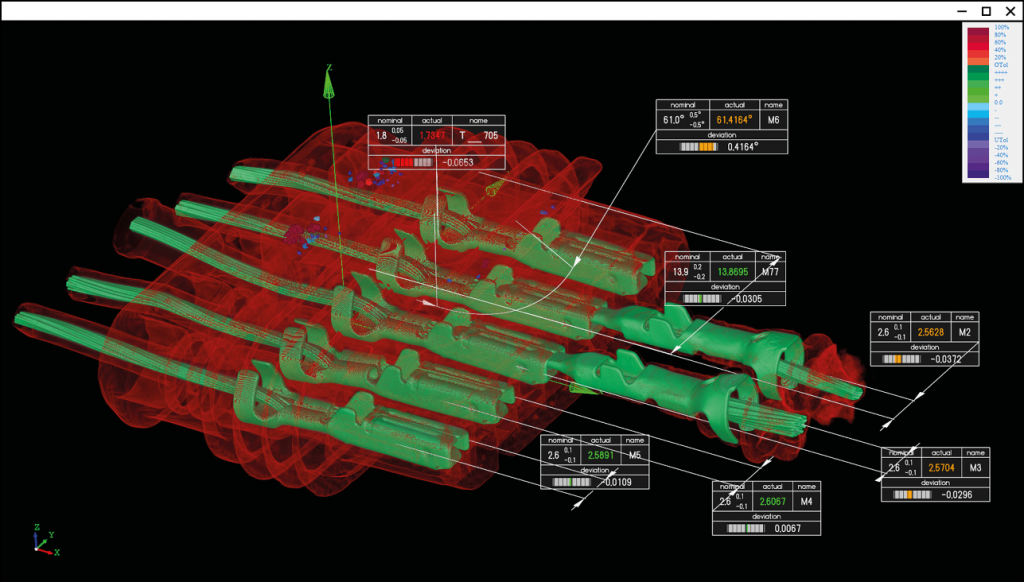

- False color matches/comparisons

- Aging analyses

- Target/actual comparisons

- Initial sample measurements / First sampling (FAIR)

- Defect analyses

- Reverse engineering

For computer tomography or X-ray tomography, we use a modern Werth TomoScope L300 in our company. Depending on the customer’s requirements and the nature of the part to be inspected, a power of up to 300 kV is possible.

Computer tomograph

| Manufacturer: | Werth |

| Max. Workpiece gr..e: | D = 470 mm / L = 678 mm (depending on the aspect ratio of the workpieces, more if necessary) |

| Accuracy: | 4,5 μm – 0,02 mm |

| Calibration: | Standard-compliant calibration according to VDI 2617 with DAkkS certificate |

| Special features: | considerable time saving due to patented stepless rotary axis |